Critical to safe and smooth rail operation is timely maintenance of rail assets and alerts about hazards along the right-of-way.

Owners must be able to minimize service interruptions for both passengers and freight while complying with statutory requirements. There are five vulnerabilities in track operation that must be carefully addressed in order to maintain safe and smooth rail operation.

.jpg?width=6000&name=Track%20Image%20(1).jpg)

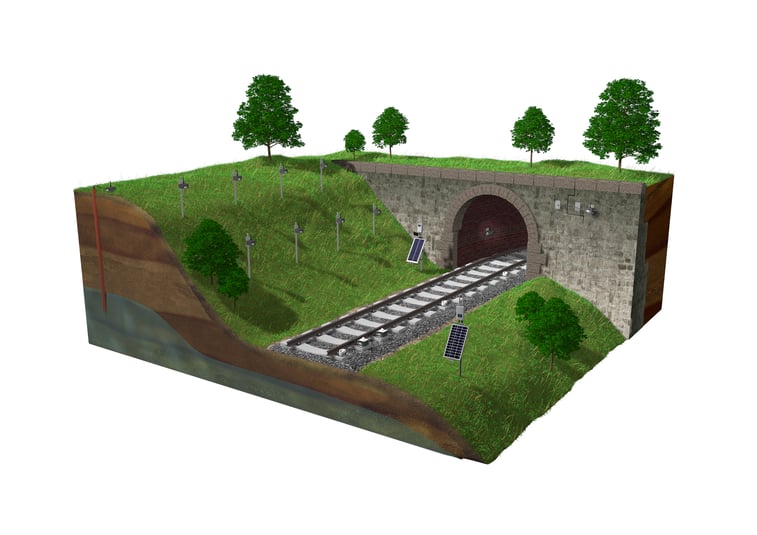

1 | Track Geometry

Detecting track movement associated with traffic loading, weather events such as flooding, maintenance and construction activity and failure of supporting materials such as track foundations or embankments is critical to the avoidance of derailments. This is important for any track, but is critical for high speed rail corridors. Tolerances need to be maintained to avoid costly derailments as we have seen throughout the U.S. in the last decade.

In areas prone to trackbed movement, or adjacent to active construction, visual inspection is no longer adequate given the demand on freight and passenger train schedule and the cost and time impact these inspections require. Senceive has developed wireless sensors that are built for the challenges of rail applications. They are quick to install and provide precise measurement for many years after installation, operating in remote locations and can be reused on multiple projects. Owners can use the data to prioritize maintenance resources, to evaluate the effectiveness of interventions such as tamping or ballast cleaning, or to determine whether pre-identified movement has stabilized or is ongoing.

A wide range of track, trackbed and track geometry defects and parameters can be measured, including:

- cross-level

- twist

- slew

- settlement

- temperature

- soil moisture content.

Sensors are usually fixed to track ties, but can easily be mounted on other track assets such as gantries, platforms and undertrack culverts. Wireless monitoring provides an alternative or a supplementary approach to optical methods such as robotic total station and mobile solutions such as track recording vehicles. Wireless systems can also be used alongside railway void meters and other track measurements systems.

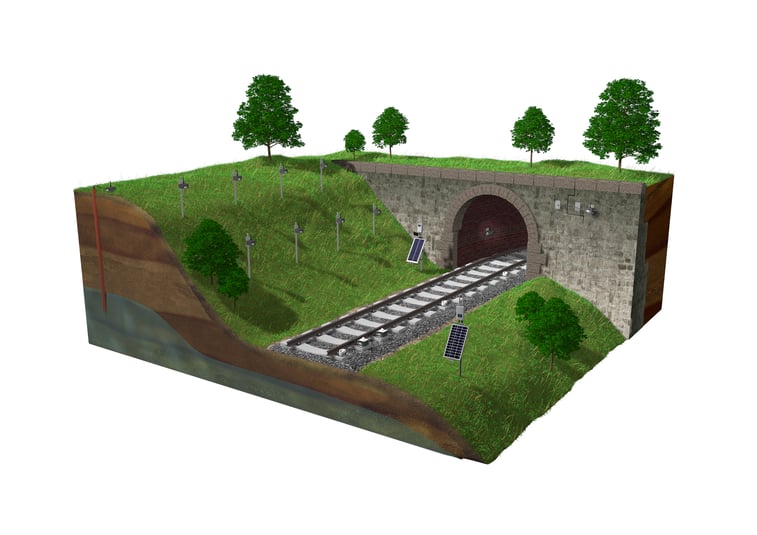

2 | Landslides

Landslides and landslips are becoming more frequent worldwide as the climate changes and extreme weather events become more frequent. Having visibility on soil and debris on the track before trains arrive can help avoid derailment and damage to rolling stock and harm to the passengers.

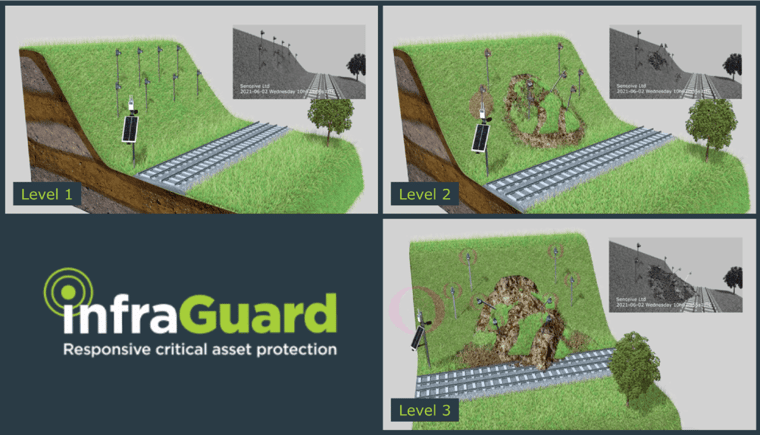

In response to these challenges, Senceive engineers have worked with rail operators to develop a responsive wireless monitoring solution to detect sudden ground movement. In use since 2018, InfraGuard™ is the world’s most widely used wireless remote monitoring solution for near real-time alerts of landslides, rockfalls, and embankment failures. The system is:

- simple and quick to install

- precise

- robust

- responsive

- can operate independently for more than a decade with minimal maintenance

- provides movement data with photo imagery so you can judge what steps to take without putting boots on the ground.

It is the ideal slope stability monitoring tool when you need effective event detection at a reasonable cost.

InfraGuard™ has been proven again and again - preventing trains from hitting track obstructions since 2018. Find out more here.

3 | Adjacent Construction

Construction, rehabilitation and maintenance activity can have potentially damaging structural effects on adjacent structures and property. Risk mitigation is key to reducing liability and the vulnerability of assets during adjacent construction.

Owners can use wireless monitoring technology such as precise tilt sensors and crack sensors to safeguard infrastructure and protect their interests in the event of claims by providing objective time-based data that can encompass structural and geotechnical deformations which can result in problematic rotation, convergence, settlement and cracking.

Sensors are remarkably small – little bigger than a tennis ball – which means that most people will not even notice that a monitoring program is taking place. The sensors are built to withstand the challenges of rail and construction site conditions as well as harsh weather conditions and because there are no power or comms cables, there is minimal risk of the system being damaged.

4 | Tunnels

Other vulnerable assets in a rail owners inventory include tunnels. Nearby construction, utility failures leading to seepage, inadequate ground investigation and/or support are all common causes of tunnel failure. With a well-designed monitoring program in place, small changes in tunnel alignment can be easily detected prior to significant movement or collapse.

Tunnel construction and maintenance professionals worldwide choose Senceive wireless condition monitoring technology to assess structural and ground behavior throughout the life of underground assets.

Precise movement sensors can be mounted to virtually any surface and can deliver data at set intervals (typically not more than every 30 minutes) on parameters including convergence, settlement and cracking. A wide range of third-party sensors can be integrated with Senceive wireless platforms to provide data on engineering parameters such as strain, torque and ground water pore pressure.

Innovative solutions are available to transfer data from underground sites using a combination of radio, wi-fi and cabled communications infrastructure.

Wireless monitoring has many advantages over more traditional methods:

- instruments are so small they do not compromise clearance.

- they are tough and able to withstand the extremes of temperature, impact and vibration.

- they work in conditions that would compromise optical monitoring methods such as AMTS (i.e., where dust or physical obstructions would prevent continuous line of sight.)

- quick and simple to install and can be moved as tunnelling progresses.

- can also be left in place for many years with minimal maintenance – providing a highly cost-effective and safe monitoring solution.

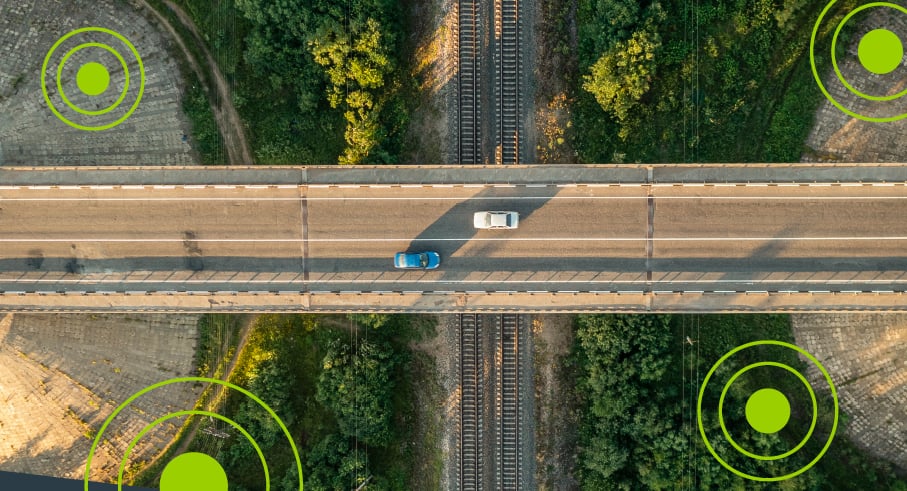

5 | Bridges

Engineers and asset managers face challenges related to the age and deterioration of their bridges and their exposure to extreme events such as flooding and impact damage. Gaining access to inspect and maintain the structures is costly, particularly between predetermined inspection intervals.

Wireless monitoring can help protect bridge infrastructure by safeguarding vulnerable structures and extending asset life. Users can:

- get early warning of structural instability, distress & defects without leaving your desk

- combine various sensors to get the insight you need: crack sensors, temperature, cameras, strain, deformation, settlement, rotational movement

- install monitoring system in hours and stay informed for years – typically 10 to 15 years.

Wireless monitoring can also help protect the traveling public and the people responsible for maintaining and working on these structures by:

- getting automated near-realtime alarms when trigger levels are breached and early warning of structural instability, sudden impact damage and longer term distress. Senceive’s unique InfraGuard solution combines movement alerts with site imagery so you can avoid false alarms and act fast in real emergencies.

- getting the bigger picture from hundreds of sensors checking the performance of all the key structural elements – on a 24/7 basis.

- installing an emergency monitoring kit within hours of an event to assess ongoing movement.

Staying on Track

These five vulnerable areas can lead to service interruption, damage, injury, or even death. Mitigating the associated risks can be crucial to protect rail assets and public safety, as well as the bottom line. Senceive specializes in helping clients protect rail assets and has developed technology with the rail industry in mind. Providing wireless, ruggedized sensors with low clearance and long battery life that are built to operate and communicate in remote environments, Senceive’s systems are the most used wireless track condition monitoring system in the world.

For More Information: Please contact a Senceive Rail Expert in North America today at (281) 881-9570 or usa_info@senceive.com.

![]() This is not the case with modern systems.

This is not the case with modern systems.

.jpg?width=6000&name=Track%20Image%20(1).jpg)